Manufacturing

Techniques and products tailored to the customer

Manufacturing

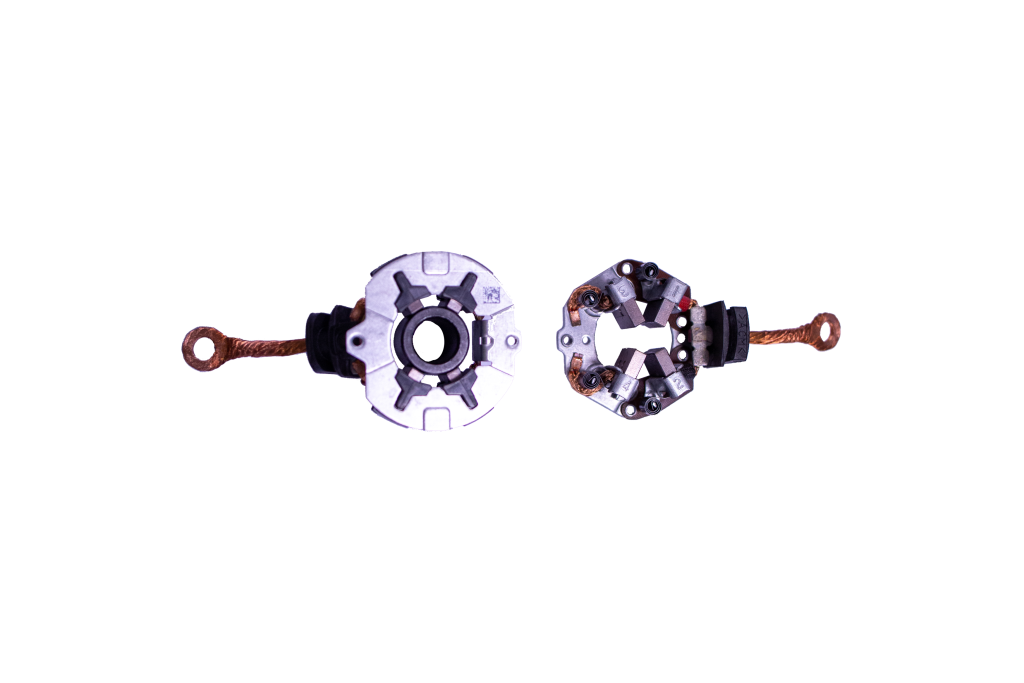

Automated processes: welding of fuses and brushes, riveting of drawers for brushes, insertion of springs, final electrical testing

Cutting, crimping, insertion of rubber pads, up to the complete construction of a wiring

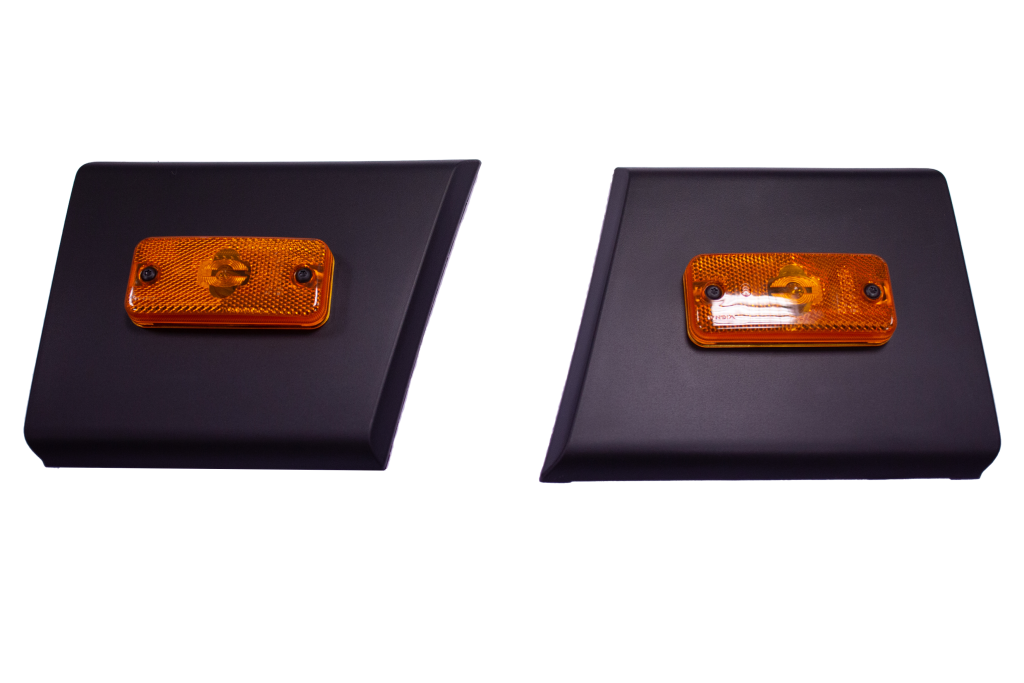

Manual and automatic insertion of pinets on shovels and escutcheons in the automotive sector

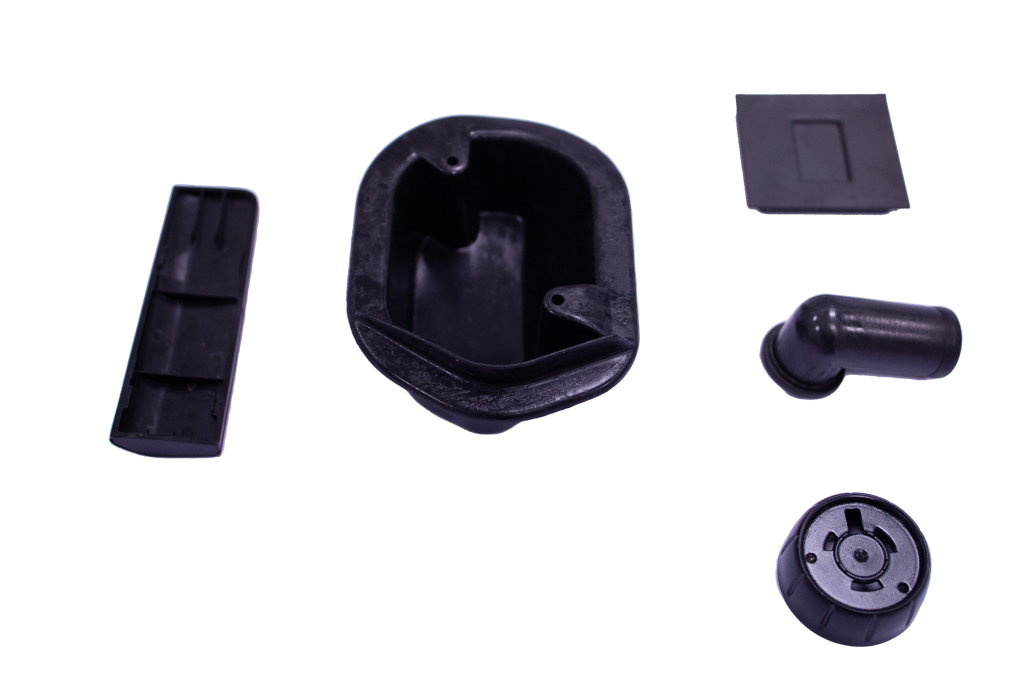

Lever molding and co-molding

Assembly of rubbers and bushings on the levers

Motor hood assembly

Plastic molding of components of moderate size

Details on some of our processing tools

- Presses for molding and leverages co-molding.

- Presses for plastic molding.

- Robotic welding stations.

- Equipment for riveting brush-holder boxes for the construction of ignition groups. Machine cuts, peels, crimpes complete with automatic insertion of rubber pads and load cells; 3D control equipment.

Production segmentation

Our production is mainly concentrated on wiring, which cover 33% of the total. The ignition groups follow, then the moldings, the covers and finally the levers.